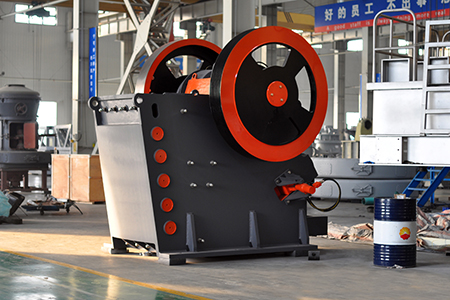

كسارة فكية متنقلة

وتتميز كسارات الفك الابتدائي المحمول من تصمي

وتتميز كسارات الفك الابتدائي المحمول من تصمي

هو بحث نوع الزاحف سحق المحمول ومصنع الفرز ومص

اسطوانة واحدة كسارة مخروطية هيدروليكية لدينا

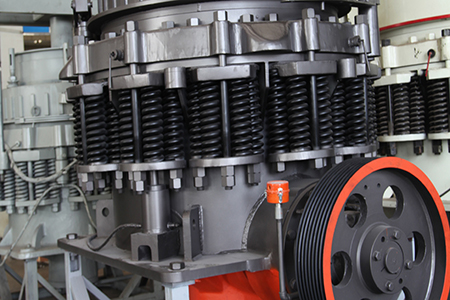

سلسلةCSكسارة مخروطية الزنبركية هي التي تتخذ ش

كسارة تصادمة التي اتخذ بمعروف صنع الفنية، وتص

لمحرك يدفع سيور وبكرة، تحرك فك المحرك من فوق ا

إن كسارة الحصى التي تم تصميمها وتصنيعها بواسطة Aimix Group تتبنى التكنولوجيا المتقدمة ولديها العديد من مزايا الأداء ، مثل نسبة التكسير الكبيرة ، وكفاءة التكسير العالية ، وعمر الخدمة الطويل ...

More

كسارات عدد 436 عروض سعر يبدأ من €17,000 جديدة و مستعملة بائعون محل ثقة متاح في المخزون ماكينات متخصصة بجودة عالية للبيع في Machineryline المملكة العربية السعودية

More

وتعمل الشركة في عدة قطاعات، بما في ذلك مجالات الكسارات والتعدين وإنتاج البحص المصنَّف وتمهيد الإسفلت والتصنيع وقطع الغيار ووسائل النقل.

More

2021年9月7日 مشروع كسارة بحص - مشروعك السعودية. طلب الدراسة. عبارة عن كسارة بحص حيث تأتى أهمية المشروع من الطلب المستمر على منتجات التشييد والبناء والطفرة الهائلة فى شتى المجالات الصناعية والإسكانية. رأس المال 16,875,000. معدل

More

الشركة السعودية للخرسانة الجاهزة، شركة رائدة في إنتاج وتوريد الخرسانة الجاهزة والمنتجات الأخري ذات الصلة، في المملكة العربية السعودية.

More

ويوجد لدينا كسارة واحدة للرمل الأبيض سيليكا وهي تقع في منطقة المجمعة بالرياض. تتميز كسارارتنا بالجودة ومراعاة المواصفات التي تجعلنا ننفرد بثقة عملائنا في الدمام - المنطقة الشرقية وأيضا في الرياض والمدينة المنورة. كسارات المدينة المنورة. أنواع الكسارات.

More

أن نكون الشريك الاستراتيجي الوطني في حلول قطاع التعدين والبناء في المملكة العربية السعودية. الرسالة بناء شراكات استراتيجية مع العملاء وتقديم حلول التعدين والبناء من خلال كوادر وطنية مؤهلة لبيئة مستدامة تحقق تطلعات ...

More

Following the amalgamation of the Kingdom of Hejaz and Nejd, Abdulaziz bin Saud issued a royal decree on 23 September 1932 naming the new state al-Mamlaka al-ʿArabiyya as

More

سعر آلة كسارة الطوب في المملكة العربية السعودية. البازلت سحق في المملكة العربية السعودية للبيع.

More

معلومات عن الشركة. تأسست )حديد ( ومقرها الجبيل عام 1979 م، وهي مملوكة بالكامل ل)سابك (. بدأت الإنتاج عام 1983 م، حيث تنتج أسياخ وقضبان التسليح ولفات الأسلاك والمقاطع الحديدية ومسطحات الصلب . وتستخدم الحجر الجيري وخام الحديد والخردة والغاز

More

معلومات عن مصنع إعادة تدوير البلاستيك في المملكة العربية السعودية. الموقع: المملكة العربية السعودية; يشمل مصنع إعادة تدوير البلاستيك: كسارة البلاستيك، آلة تكوير البلاستيك، غسالة البلاستيك ...

More

خدمات جمع وإعادة تدوير المخلفات البلاستيكية الصناعية والتجارية والزراعية. تساعد نابكو الوطنية عملائها في المملكة العربية السعودية على تحقيق اهداف الإستدامة البيئية، من خلال العمل معاً على خطة استدامة تشمل تقديم ...

More

كسارة حصاة لمصنع سحق في المملكة العربية السعودية . معالجة الفحم تجهيز الحزام . معدات كسارة الحجر في المملكة العربية السعودية.

More

برعاية كريمة من صاحب السمو الملكي الأمير محمد بن سلمان بن عبد العزيز ولي العهد، أطلق معالي وزير الصناعة والثروة المعدني الأستاذ بندر بن ابراهيم الخريّف برنامج صنع في السعودية بتاريخ 15 شعبان 1442 الموافق 28 مارس 2021.

More

تود سفارة المملكة العربية في جمهورية مصر العربية إحاطة المواطنين السعوديين الكرام المقيمين والزائرين لمصر، باللقاء الأسبوعي مع السفير في يومي الثلاثاء والخميس من كل أسبوع عند الساعة الحادية عشر صباحاً، وذلك بمقر ...

More

وزارة الصناعة والثروة المعدنية. الوزارة المعنية بالإشراف على قطاعي الصناعة والتعدين في المملكة العربية السعودية، وتشجيع المستثمرين فيهما، واكتشاف واستغلال موارد المملكة من الثروة المعدنية وتحقيق أعلى مردود منها.

More

ومن المتوقع أن يصل سوق الأسمدة في المملكة العربية السعودية إلى 694.74 مليار دولار أمريكي في عام 2024، وأن ينمو بمعدل نمو سنوي مركب قدره 7.40٪ ليصل إلى 992.75 مليار دولار أمريكي بحلول عام 2029. شركة معادن للفوسفات، الشركة السعودية ...

More

مدير مالي. انضم السيد كامل إلى الشركة السعودية للخرسانة الجاهزة في عام 2015 ويمتلك خبرة أكثر من 20 عاماً في الشركة المتعددة الجنسيات والشركات المحلية المختلفة.

More

مع توسع الاهتمام بالطاقة المتجددة والتطور الملحوظ على مدى العقدين الماضيين، ركزت المملكة العربية السعودية على تنمية هذا القطاع. حيث بدأت العديد من الاستثمارات الضخمة تؤتي ثمارها، خاصة بعد أن كشف وباء كوفيد-19 عن دور ...

More

2023年10月6日 يجب على المستوردين المحليين في المملكة العربية السعودية اتباع هذه الخطوات بجد لضمان الامتثال وجلب مجموعة واسعة من المنتجات بنجاح إلى البلاد ، بما في ذلك الفواكه الطازجة والخضروات والفواكه المجمدة والخضروات ...

More

مصنع كسارة الحجر الجيري المتنقلة في المملكة العربية السعودية . انت هنا حاليا! صفحة رئيسية; مصنع كسارة الحجر الجيري المتنقلة في المملكة العربية السعودية

More

كسارة وطاحونة لمصنع المحجر في جيزان السعودية. حجر كسارة التلفيف الأرشيف كساره للبيع حي السويس . 7 500 000 ج م للبيع كساره في حالة الزيروه كسور لوكومو موديل 98 هيدروليك 11085 حجر 2 جديد فيدر بمحتوياته مير 1313 1 مهزه 4 دكه 2 متر 1 ...

More

خدمات جمع وإعادة تدوير المخلفات البلاستيكية الصناعية والتجارية والزراعية. تساعد نابكو الوطنية عملائها في المملكة العربية السعودية على تحقيق اهداف الإستدامة البيئية، من خلال العمل معاً على خطة استدامة تشمل تقديم ...

More

دراسة اقتصادية لأهم محاصيل الزيوت فى مصر = مجلد 6 عدد 3 March 2015 01/03/2015 الخارجي لتحقيق الأمن الغذائي للقمح في المملكة العربية السعودية = لممارسات الزراعة العضوية والزراعة التقليدية في بعض

More

كسارة مخروطية حصاة السعر في المملكة العربية. 2021-9-26 كسارة مخروطية فولاذية للبيع في السعودية آلة كسارة مخروطية محمولة مستعملة في المملكة العربية السعودية.

More

كسارة الحجر في المملكة العربية السعودية أنواع كسارات الحجر المناسبة للمحاجر المغربية. الأنواع الشائعة من كسارات الحجر. هناك ثلاث فئات رئيسية من كسارات الحجارة المستخدمة في صناعة المحاجر:

More

ويوجد لدينا كسارة واحدة للرمل الأبيض سيليكا وهي تقع في منطقة المجمعة بالرياض تتميز كسارارتنا بالجودة ومراعاة المواصفات التي تجعلنا ننفرد بثقة عملائنا في الدمام - المنطقة الشرقية وأيضا في الرياض والمدينة المنورة

More

التدريب على كسارة النظام ... 50 طنًا في الساعة محطة تكسير الحجر الجيري المحمولة بقدرة 250 طنًا في الساعة المملكة العربية السعودية 600 tph محطة تكسير ...

More378 FA Tower, William SBl 2123, IL, US

(+990) 698 598 631

Opening Hours: 9:00 - 6:00

Copyright © itpart all rights reserved.